The evolution of computerized systems for the production of dental restorations associated with the development of new ceramic material microstructures has caused a significant change in the clinical workflow for dentists and technicians as well as the treatment options offered to patients. One of the most important changes in this scenario has been the introduction of monolithic restorations made from high-strength ceramics, such as zirconia.

This concept per se is not new, as ceramic materials have been used for the production of monolithic restorations for a relatively long time, but it was only when zirconia began to be used to produce full-contour crowns that dentists and technicians became more confident in indicating a ceramic material for crowns and bridges in the subsequent area. In fact, by offering monolithic prostheses, clinicians are able to overcome one of the major problems associated with multilayered restorations, which is the fracture of the low-strength veneering layer , usually made from a feldspathic dental ceramic. However, certain health issues can occur by utilizing a monolithic zirconia repair and ought to be taken care of, such as wearing antagonist dentition and maintaining the natural dentition 's cosmetic characteristics .

Classification of ceramics

Dental ceramics can be categorized

in a number of ways, including form, manufacturing procedure, temperature

fusion, microstructure, translucency, fracture resistance and abrasivity.

Classification by Composition

Ceramics can be classified into

three groups by composition2: ceramics that compose primarily of glass, those

composed of particle-filed glass, and polycrystalline ones. Ceramics which

consist mainly of glass have the highest esthetics. Often manufacturers add

small amounts of filer particles to monitor the optical effects which mimic

natural enamel and dentin. Generally speaking, the more filer particles added

to a ceramic, the greater the increase in the mechanical properties but the

greater the decrease in the esthetic characteristics. Polycrystalline ceramics

contain absolutely no glass. These aren't porcelain as noted earlier.[2]

Classification by Processing Method

Another approach to the

description of ceramics is by the method of manufacturing them. This includes

the production of powder / liquid, slip casting, hot ceramic pressing, and

computer-aided additive and subtractive design / computer-aided manufacturing

(CAd / CAM).

Classification by Fusing Temperature

Dental porcelain is defined by the

temperatures of its fiing. These groups are defined as high-fusing (1300 ° C),

medium-fusing (1101 ° C to 1,300 ° C), low-fusing (850 ° C to 1,100 ° C), and

ultra-low-fusing (< 850 ° C). 7 Denture teeth are a case in point of high

fusion porcelain. Depending on the system, crown and bridge porcelain may be

medium- or low-fusing, and ultra-low-fusing porcelain would be used for

porcelain and glazing. Some now apply to just two categories — high- or

low-fusing porcelain — with a distinction defined at 800 ° C to make it less

difficult. [3]

Classification by Microstructure

As mentioned earlier, porcelain

has two different phases: the phase of glass (responsible for esthetics) and

the phase of crystalline (related to mechanical strength). In the case of

feldspathic porcelain, when feldspar is melted, crystalline mineral called

leucite (potassium-aluminum-silicate) forms. Feldspar undergoes incongruous

melting between 1.150 ° C and 1.530 ° C to form leucite crystals. Incongruous

melting is a process in which one material does not evenly melt and forms a

different material.7 The leucite crystalline phase has a diffaction index

similar to the glass matrix which, in this case, contributes to the overall

esthetics of porcelain.17The leucite content of porcelain is associated with

the propagation resistance of cracks. Greater content of leucite means a

greater decrease in the propagation of a crack.18 This type of porcelain is

called leucite-reinforced. Microporosities are formed on the surface during the

sintering process of all-ceramic restorations which lead to crack initiation

and propagation and ultimately result in failure. [4]

Classification by Fracture resistance

A quantitative means of describing

the tolerance of a ceramic to brittle fracture when a crack is present is

called the "fracture toughness," which is the capacity to tolerate

crack growth.1 When a substance has a high value of fracture toughness, it is

likely to undergo ductile fracture. Brittle fracture is very characteristic of

materials with a low fracture toughness value.48 Flexural strength (rupture

module or bend strength module) is defied as the ability of a material to

withstand deformation under load. Flexural strength reflects the maximum stress

encountered in the material at the time of breakup and is measured in terms of

stress.7 For example, the estimated flxural strength values for zirconia vary

from 900 MPa to 1,100 MPa,49,50 and fracture was estimated from 8 MPa to 10

MPa. [5]

Classification by Abrasiveness

Ceramic restorations were known to

induce opposed enamel wear. 53 The abrasiveness of a dental ceramic is

determined primarily by the smoothness of the material. 54 For wear to occur,

friction must evolve by mechanical interlocking of the two wear bodies. Low-fusing

porcelain was developed with the idea of reducing the abrasiveness of the

ceramic surface to incorporate fier-sized leucite particles in lower

concentrations. [6]

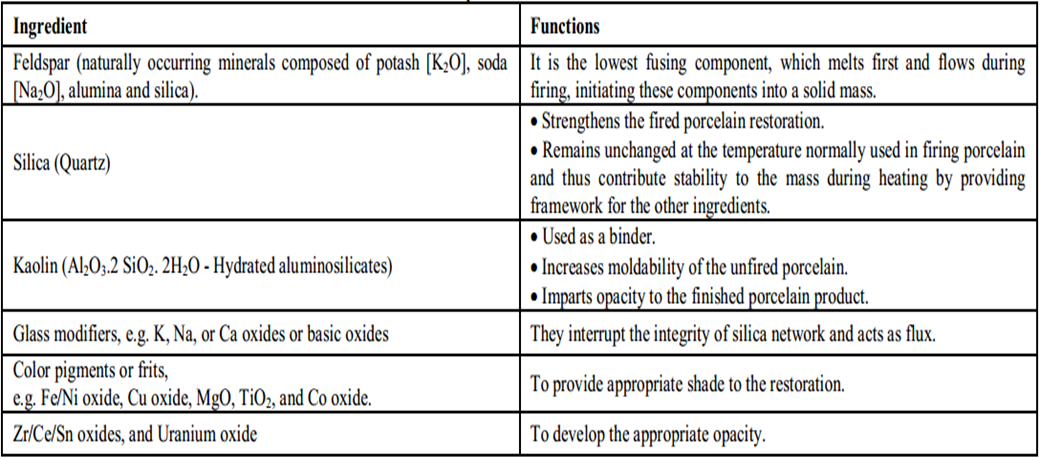

Composition

Dental ceramics are composed primarily of crystalline minerals and matrix

glass. Crystalline minerals include feldspar, quartz and alumina and maybe

kaolin as a matrix of glass. Table 1 discussed the detailed composition of the

dental ceramics [7]

Zirconia phases

Zirconia (ZrO2) also occurs in

several phases: monoclinical, tetragonal, and cubic. Zirconia is monoclinic

until 1170 ° C. It then converts to tetragonal until a temperature of 2370 ° C

reaches. At this temperature, zirconia becomes cubic until the melting point is

at 2680 ° C. (Figure 1)shows those major zirconia polymorphs. Phase transitions

of Zirconia are reversed after cooling and followed by volume expansions. With

a change of the theoretical density from 6.06 to 6.1, cubic zirconia transforms

under 2370 ° C into tetragonal. The tetragonal phase transforms to monoclinic

at around 1170 ° C, and the density decreases from 6.1 to 5.83. The

transformations into the monoclinical phase are obviously accompanied by volume

expansions of approximately 4%. The transformed grains undergo volume-induced

strains and changes of shape induced by phase transformation, accompanied by

strains of shear. These strains apply stress to grains adjacent to them. Thus

sintered pure zirconia suffers a microscopic cracking, which limits its use as

refractory ceramics or pigments. This condition improved in 1929, when zirconia

stability was first achieved.

Additives to zirconia such as

calcium oxide, magnesium oxide, cerium oxide and yttrium oxide are used to

stabilize high-temperature phases and are given the name "Partially

Stabilized Zirconia (PSZ)." At room temperature, PSZ as a biomaterial

contains the cubic phase as the major phase and the monoclinic phase as the

minor phase. Another minor phase of PSZ is the metastable tetragonal phase,

which exists by a quantity that depends on many "material design

parameters" such as stabilizer quantity, zirconia and stabiliser particle

sizes, chemical history, and processing method. The processing method affects

the homogeneity of the end powder mix and the final shape of the particle,

which affects the surface area. The residual stresses in the bulk are dependent

on the cooling procedure for the sintered product, and the more likely the

required phase transformation will take place by decreasing it.

The tetragonal metastable phase

helps enhance the toughness of the fracture through a mechanism called

toughening transformation. It is magnified at the crack tip as a force is

applied, which is called force concentration. The magnified stress will exceed

a value necessary to establish transformation of the tetragonal – monoclinic

process. This is combined with an extension of length, and would apply a

compression on the edge of the crack. As a result, crack growth is retarded and

the resilience of the cracks is decreased. The removal of some of the crack

energy that is caused by phase transition also leads to retarding the crack and

improving the resilience of the fracture. Obviously, the increased toughness of

the fracture improves the product 's reliability and increases its service life

[8].

Stabilization of zirconia

Zirconia (ZrO2) has three

polymorphic forms: tetragonal, monoclinical and cubic. At room temperature, the

monoclinic phase is stable; the tetragonal phase is a metastable process

developing at 1170–2370°C; and the cubic process starts to develop above

2670°C. The cubic – tetragonal transition takes place on cooling from high

temperature with a small expansion of the volume of the unit cell. In the other

hand, high-volume expansions (3 percent – 5 percent) follow the

tetragonal–monoclinic and cubic–monoclinic transitions. Therefore the sintered

pure zirconia undergoes the development of cracks during the cooling process

caused by significant stresses. To overcome this difficulty, oxide additives,

such as CaO, MgO, and Y2O3, are used when cooled from the sintering temperature

to room temperature to stabilize the cubic or tetragonal phase of zirconium. So

the powder of zirconia is called stabilized zirconia.

The addition of approximately 8

mol percent CaO or MgO creates partly stabilized zirconia (PSZ), i.e. during

cooling, the cubic or tetragonal transition to monoclinical phase is bounded,

and thus crack forming does not occur. Roughly speaking, the monoclinic phase

mount is about 10 percent -20 percent and can be lowered by thermal ageing to

less than 5 percent. With PSZ, improved mechanical properties are obtained due

to the toughening transformation (TT) phenomenon. TT is an induced transition

of the tetragonal phase into the monoclinical phase that is exacerbated by

access to crack energy from stress. Within several microns of the crack tip,

the grains which make up the microstructure turn into monoclinic. The volume

expansion is followed by compressive stress which prevents the propagation of

cracks.

Completely yttria-stabilized

zirconia (Y-TZP) with about 8 mol percent Y2O3 can be achieved. Because of the

increased homogeneity of the powders and the smaller particle size of the

zirconia and Y2O3 additive, 5 and 3 mol percent of Y2O3 was adequate for

complete stabilisation with the advancement of powder technologies. Currently,

an addition of 3 mol percent of Y2O3 to produce stabilized tetragonal zirconia

powder, or polycristals (3Y-TZP), is commercially available as nanopowder and

is often used in the production of sintered zirconia.

Zirconia is often produced with

the help of decomposition agents via the decomposition of zircon (ZrSiO4) and

followed by a purification phase. Specifics of the process depend on the

existence and desired properties of the raw materials. Low-temperature

high-purity zirconia tetragonal can be produced using a special technique

called the sol – gel process. The sol – gel cycle usually involves acid

dissolving a salt of zirconium accompanied by nucleation and development of

zirconia. So the sol – gel technique is used to produce nanosized zirconia by

controlling the growth of the particles. Other chemical techniques are

available for preparing zirconia, but are not covered in this book. One of the

benefits of the sol – gel process is that it can integrate additives, such as

Y2O3, during the process. Therefore a high degree of homogeneity and particle

size regulation is achieved which helps to stabilize tetragonal zirconia.

In the mid-1980s MgO-PSZ was

introduced as a bioceramic for the production of ball heads to replace total

hips. Better wear resistance, strength of bending, and toughness of fracture

were obtained compared with alumina. By comparison, the large grain size of the

sintered substance (40–50 μm) increases the wear rate of the acetabular portion

of polyethylene. Thus yttria-stabilized tetragonal zirconia ball heads were

added, as the sintered product's submicron grain size greatly improves wear

properties.

The manufacturing process of

yttria-stabilized tetragonal zirconia involves a precise and complicated heat

treatment program which ensures precipitation of the tetragonal acicular phase

at the cubic phase's grain boundaries. The durability of zirconia was found to

be highly dependent on these processing conditions. Furthermore, the

environmental conditions the implant faces also affect zirconia stability.

Explicitly, the zirconia implant surface is exposed to the implant 's body

(synovial) fluid, which causes implant degradation at low temperatures (LTD).

LTD is the monoclinic phase increase that contributes dramatically to the

ruggedness improvement. The LTD impact can be minimized by over-stabilizing the

tetragonal process by a small rise in the stabiliser. In the other hand,

improved stability does not impede the TT and the mechanical properties should

be that accordingly. These complexities pose a minor downside for the

operation. The production of zirconia balls has since been slowly reduced [8,

9].

Properties of zirconia

An excess of raw materials such as

zirconia minerals (ZrSiO4) and baddeleyite (β-ZrO2) can be found in nature for

the manufacture of zirconia (about 0.02 percent of the earth's crust). Big

zirconia deposits are present in Brazil as baddeleyte while they can be found

in Australia and India as ZrSiO4.

Zirconium is a transition metal

element, and as a white and ductile metal it has a pure crystalline shape and

as a blue-black powder it has an amorphous form. Even as expanding, it is the

18th element in the earth 's crust, zirconium can be present in nature either

in association with silicate oxides or as free oxide. Zirconia takes place in

three phases: monoclinical (m), cubic (c), and tetragonal (t). The monoclinic

phase is stable up to 1170 ° C in pure ZrO2; but the transformation on cooling

appears under 1170 ° C at 100 ° C. When it cools down it has 3-4 per cent

volumetric expansion. The cracks may appear as this change in volume is enough

to exceed the ZrO2 elastic limit. Passerini and Ruff et al., quoted by Lughi V,

found that by alloying it with other cubic oxides, called stabilizers, zirconia

can remain stable at room temperatures. Until now, the most widely used

stabilisers for the application of biomaterials are CaO, MgO, Y2O3 and CeO2,

but only ZrO2-Y2O3 has a norm of self-ISO for surgical use[10].

Biocompatibility

No local or systemic cytotoxic

symptoms or allergic reactions have been observed after detailed

biocompatibility tests of the zirconia. It has been shown acceptable for the

bone response of zirconia in vivo and for the inflammation adjacent to

zirconia. Additionally, bacteria and pathogen appear to adhere just as much to

zirconia as other materials do[11].

Optical characteristics

The most important components of

presentation of an esthetic tooth are: light, fluorescence, opalescence and

translucency. One big downside of restorations of complete contour zirconia is

its opacity[12].

Translucency

Colored zirconia with improved

translucency has been developed recently to precisely match human teeth

colours. The new material's flexural strength is 900-1400 MPa, and has a crack

tolerance of up to 6 MPam 1/2. Such conveniences have made it widely used by

the Zirconia for inlateral applications of crowns and bridges. It is necessary

to replicate the translucency of the natural tooth for excellent esthetics,

since it provides an enchanting natural appearance of the prothetics.

Translucency is the property of the surface which allows the passage of light

and its dispersion, and then the objects are not clearly seen through the

material. This property could be defined as a state between total obscurity and

transparency. Translucency can be controlled by monitoring light absorption,

reflection, and propagation through the material. The translucency is higher

when there is low resistance and fast transmission. It has been stated in a few

studies that translucency is influenced by the thickness of the layer and by

the grain size [13].

X-ray opacity

Dental restorative materials have

varying degrees of opacity and provides useful diagnostic information. The

zirconia may be added in composite materials for dental filling because it

represents an opaque X-ray agent. In a research conducted to assess zirconia's

X-ray hardness, four different materials (pure titanium, NANOZR, Y-TZP, alumina

plates) were measured against an X-ray agent with the same thickness (0,2-2 mm)

and human tooth. Y-TZP and NANOZR have been found to exhibit increased

opacity[14].

Wear behavior

It is important to determine the

wear behaviour of monolithic zirconia restorations, but the wear of the enamel

of natural antagonists teeth in comparison to the zirconia material is of

greater clinical importance[15].

A natural occurrence of human

dentition is gradual wearing of teeth. Many factors contribute to the dental

wear such as diet, bruxism, strength of the oral muscles, thickness and

toughness of enamel, pH and quality of saliva and dental content. Each of these

variables have specific wear habits that often change the wear cycle. If we use

restorative fabrics with specific wear rates, the physiological wear is changed

[16].

Processing methods

CAD / CAM components used in

dental restorations are typically totally or partly sintered blocks and disks.

The state of those blocks and disks differentiates dental restoration

manufacturing.

With two different methods, dental

prosthetic restorations made from zirconia can be achieved using the CAD-CAM

technology [17].

In the first technique, the prothetic

restorations are milled from already sintered zirconia blocks, which means that

there is no shrinkage to the final structure, but there are certain

disadvantages, such as the reduced lifespan of the burs, due to their high wear

and the numerous flaws that occur during the machining process, which can

diminish the mechanical properties of the final prothesis. In this process, at

temperatures below 15000C, the Y-TZP blocks are subjected to a first

sinterization, increasing their density. Then, in an inert gas atmosphere, the

blocks are subjected to high pressure at the same temperatures, which allows

the obtaining of a very high density of more than 99 % of the theoretical one

[18].

In the second method, the zirconia

prothesis is milled from a block, replicating the final prothesis shape but

with larger dimensions, thus compensating for the shrinkage after sintering.

The structure of an oversized

zirconia (Zirkonzahn Ice Zirkon Translucent) after milling is shown in Figure

2.

The ceramics are then fired and

the structure contracts to the final level. After a cold pressing process,

which compacts the zirconia powders, the non-sintered zirconia blanks lead.

Through this way we obtain a very low pore size and a strong part distribution

inside the blank . The next step is the machining of various metal solutions

(cerium, bismuth, iron or a combination of them) by immersion and the coloring

of the restorations. As it passes through the last phase of sintering the color

develops. The concentration of the solution has a direct influence on the final

shade. A satisfactory coloring can be achieved by concentrations as low as

0.01mol percent. For a good result, we must follow the instructions of the

manufacturer as the final sintering temperature influences the color obtained.

At the end of the sintering process, the zirconia frame acquires its final

mechanical properties when it undergoes a contraction of about 25 per cent,

which means it returns to its correct dimensions. It is imperative to know the

exact volume shrinkage information for each blank block of zirconia to optimize

the fit of the restore. The vast majority of blocks have barcodes which give

the computer information about the density of the milling block and so we can

over-size the frame appropriately [19].

Milled frame of bulky zirconia,

separated from the blank, can be seen in Figure 3. In the final stages,

sintering is mandatory to remove any tension caused by the operation of surface

milling and to obtain the required density.

A multilayer coating technique is

used to veneer zirconia frame with compatible ceramics to create an aesthetic

look of the zirconia ceramic reconstruction. Figure 4 displays the layers of

Zirkonzahn Ice Zirkon Ceramics added (Ceramic Dentine A1, Ceramic Enamel S1,

Ceramic Transpa Neutral)

Uses of zirconia

Although there are currently many

types of zirconia-containing ceramic systems available, so far only three are

used in dentistry. These are polycrystals of yttrium cation doped tetragonal

zirconia (3Y-TZP), partially stabilized magnesium cation doped zirconia

(Mg-PSZ) and zirconiatoughened alumina (ZTA)

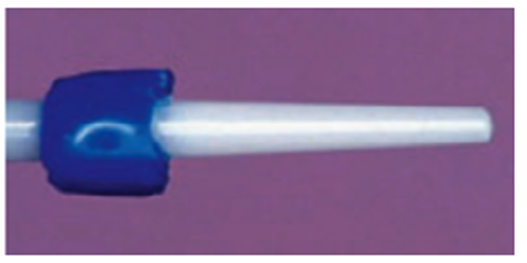

Dental posts located in Zirconia

Development of new post materials

(Figure 6) has begun the requirement for more esthetic posts, especially under

all ceramic restorations. In situations where all-ceramic restorations are used

to restore anterior teeth, metal posts can lead to unfavorable esthetic

results, such as a gray discoloration of translucent all-ceramic crowns and the

gingival margin around them. In addition, prefabricated corrosive reactions can

cause complications involving the surrounding tissues and oral environment,

including metal taste, oral burning, sensitization, oral pain, and other

reactions. These issues led to white or translucent posts made of zirconia and

other ceramic materials being created [20].

Crown and Bridge, Zirconia

Often used was the manufacture of zirconia structures for crown and bridge of either presintered or strongly isostatic pressed zirconia, as seen in (Figure 7). Zirconia systems deliver new insights in metal-free partial fixed dentures and single tooth reconstructions due to the high flexural power of more than 900 MPa of zirconium and showed positive initial clinical results[21].

Implant abutments located in Zirconia

This allowed clinicians to expand

their demand for implant-supported restorations as a result of using the

zirconia ceramics for the manufacture of tooth-supported restorations (Figure

8). The use of zirconia as implant-supported restorations is due to the greater

durability and lower zirconia elasticity modulus. Zirconia has some benefits

over alumina in stable and converted ways in order to overcome the issue of

alumina fragility and the consequent possible implant failure. These abutments

are distinguished by their color matching the tooth, their good compatibility

with the tissue and their lower accumulation of plaques[22].

Esthetic orthodontic brackets, based in Zirconia

In addition to the previously

mentioned dental applications, zirconia was also used for the manufacture of

esthetic orthodontic brackets. Polycrystalline zirconia brackets have been

offered as an alternative to alumina ceramic brackets, which are reported to

have the greatest toughness among all ceramics. They are cheaper than the

ceramic brackets of monocrystalline alumina but they are very reflective and

can display intrinsic colors making them less attractive. For both stainless

steel and nickel-titanium archwires, strong sliding properties were identified

along with decreased plaque adhesion, clinically appropriate bond strengths and

loci of bond failure at the bracket / adhesive interface. Keith et al.,

however, found no significant advantage of zirconia brackets over

polycrystalline alumina brackets in terms of their frictional properties[23].

References

1- Schley

JS, Heussen N, Reich S, Fischer J, Haselhuhn K, Wolfart S. Survival probability

of zirconia‐based fixed dental prostheses up to 5 yr: a systematic review of

the literature. Eur J Oral Sci. 2010;118(5):443-50.

2- Kelly

Jr. dental ceramics: what is this stuf anyway? J Am Dent Assoc.

2008;139(suppl):s4- s7

3- Leinfelder

KL. Porcelain esthetics for the 21st century. J Am Dent Assoc. 2000;131(suppl

1):s47- s51

4- McLean

J. The Science and Art of Dental Ceramics. Chicago, iL: Quintessence Publishing

Co inc; 1979

5- Piwowarczyk

A, Ottl P, Lauer HC, Kuretzky t. A clinical report and overview of scientifi

studies and clinical procedures conducted on 3M esPe Lava All-Ceramic system. J

Prosthodont. 2005;14(1):39-45.

6- elmaria

A, Goldstein G, Vijayaraghavan t, et al. An evaluation of wear when enamel is

opposed by various ceramic materials and gold. J Prosthet Dent.

2006;96(5):345-353.

7- Rama

Krishna Alla, Dental Materials Science, Jaypee Brothers Medical Publishers Pvt

Limited, New Delhi, India, 2013, 1st Edition, 333-354.

8- Saad

B.H. Farid, in Bioceramics: For Materials Science and Engineering, 2019

9- Kelly

JR, Denry I. Stabilized zirconia as a structural ceramic: an overview. Dental

materials. 2008 Mar 1;24(3):289-98.

10- Lughi

V, Sergo V. Low temperature degradation - aging - of zirconia: A critical

review of the relevant aspects in dentistry. Dental Materials.

2010;26(8):807–820.

11- Kenneth

JA . Dental Ceramics . In: Kenneth JA , Chiayi S , Ralph R , editors. Phillips

Science of dental materials . Elsevier ; 2013 . pp. 418 – 473

12- Al-Juaila

E, Osman E, Segaan L, Shrebaty M, Farghaly EA. Comparison of translucency for

different thicknesses of recent types of esthetic zirconia ceramics versus

conventional ceramics (in vitrostudy) Future Dental Journal. 2018

13- Tuncel

I, Turp I, Üşümez A. Evaluation of translucency of monolithic zirconia and

framework zirconia materials. J AdvProsthodont. 2016;8(3):181–186.

14- Ban S.

Reliability and properties of core materials for all-ceramic dental

restorations. Japanese Dental Science Review. 2008;44(1):3–21.

15- Stober

T, Bermejo JL, Rammelsberg P, Schmitter M. Enamel wear caused by monolithic

zirconia crowns after 6 months of clinical use. Journal of Oral Rehabilitation.

2014;41(4):314–322.

16- Kim MJ,

Oh SH, Kim JH, Ju SW, Seo DG, Jun SH, Ahn JS, Ryu JJ. Wear evaluation of the

human enamel opposing different Y-TZP dental ceramics and other porcelains.

Journal of Dentistry. 2012;40(11):979–988.

17- Bona

undefined, A undefined. D.; Pecho, O.E.; Alessandretti, R. Zirconia as a Dental

Biomaterial. Materials. 2015;8:4978–4991

18- Cavalcanti

AN, Foxton RM, Watson TF, Oliveira MT, Giannini M, Marchi GM. Y-TZP

Ceramics:Key Concepts for Clinical Application. Oper Dent. 2009;34(3):344–351

19- Russell

AG. Building Blocks. An overview of the various types of machinable blocks for

laboratory-based CAD/CAM systems. Inside Dental Technology. 2011;2(5)

20- Kedici

SP, Aksüt AA, Kílíçarslan MA, et al. Corrosion behaviour of dental metals and

alloys in different media. J Oral Rehabil 1998; 25: 800-8.

21- Sturzenegger

B, Feher A, Lüthy H, et al. Klinische Studie von Zirkonoxidbrücken im

Seitenzahngebiet hergestellt mit dem DCMSystem. Acta Med Dent Helv 2000; 5:

131-139.

22- Yildirim

M, Edelhoff D, Hanisch O, et al. Ceramic abutments--a new era in achieving

optimal esthetics in implant dentistry. Int J Periodont Restor Dent 2000; 20:

81-91.

23- Keith

O, Kusy RP, Whitley JQ. Zirconia brackets: an evaluation of morphology and

coefficients of friction. Am J Orthod Dentofacial Ortho 1994; 106: 605-14.

No comments:

Post a Comment